Artec Condenser

Artec condensers:

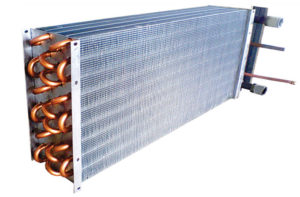

Using Inner Grooved Turbocoils in Freon systems have the highest level of efficiency and heating exchange with the appropriate thickness compatible with grooves.

Aluminum fins which are manufactured by using modern technology and designed in special grooves (turbulence) with sine waves, would bring high efficiency system with minimum difrust time.

The fins can make turbulent flow to develop the heat transfer coefficient and improve the coil efficiency. The triangular arrangement of the pipes makes the air in contact with the entire surface of the pipe. Also, the distance between the tubes is measured in a way to create a high balance between the flowing refrigerant volume and exchanging level. The coils then will be tested under 400psi Azote pressure after being cleansed and removing of grease.

After discharging the coils will again be filled with 150psi. Approved by AHRI institute, the designing of Artec coils is done via applying the most advanced software technology in the world.

All parts connected to the coils, such as tubes, underwater and … are made of aluminum sheet to prevent rottenness from contact with water. The Artec Condenser Coils are made from a 3.8mm tube, with a 2.5mm Fin Finish and with the above specifications.

Fan

The Axial fans (external rotor) used in our manufacturing line are available in different sizes of 35cm, 42cm, 5cm0 and 63cm, with speeds of RPM 1350 & RPM 1320 , with IP54 protection class and F heating class are in complete accordance with CE Europe standards.

Fan blades are made out of light Aluminum with considerable resistance and appropriate angle to air throttling. Such process can maximize the air transport volume and minimize the power consumption and noise.

Such fans are equipped with thermal protection system against extra loading and guard grills which comply with highest international standards.

Cover and chassis

In the Artec devices, the cover is made of electrostatic powder coated steel sheet, which is resistant to damage from climates or corrosion, the thickness of the sheet is selected according to the dimensions of the device to prevent body vibration.

The condenser chassis is designed to be movable according to the conditions and can be used apart from the condenser or attached to its base. The location of the compressor on the chassis has the ability to move and install a variety of compressors.